Distinctive feature

- It prevents the collapse of the borehole wall, reduces frictional resistance between the pile and the ground, and allows for smooth pile extraction.

- It is soluble in liquid and can easily create drilling mud in small quantities.

- This is a “Made in Niigata” registered product. Registration number: 2022K101

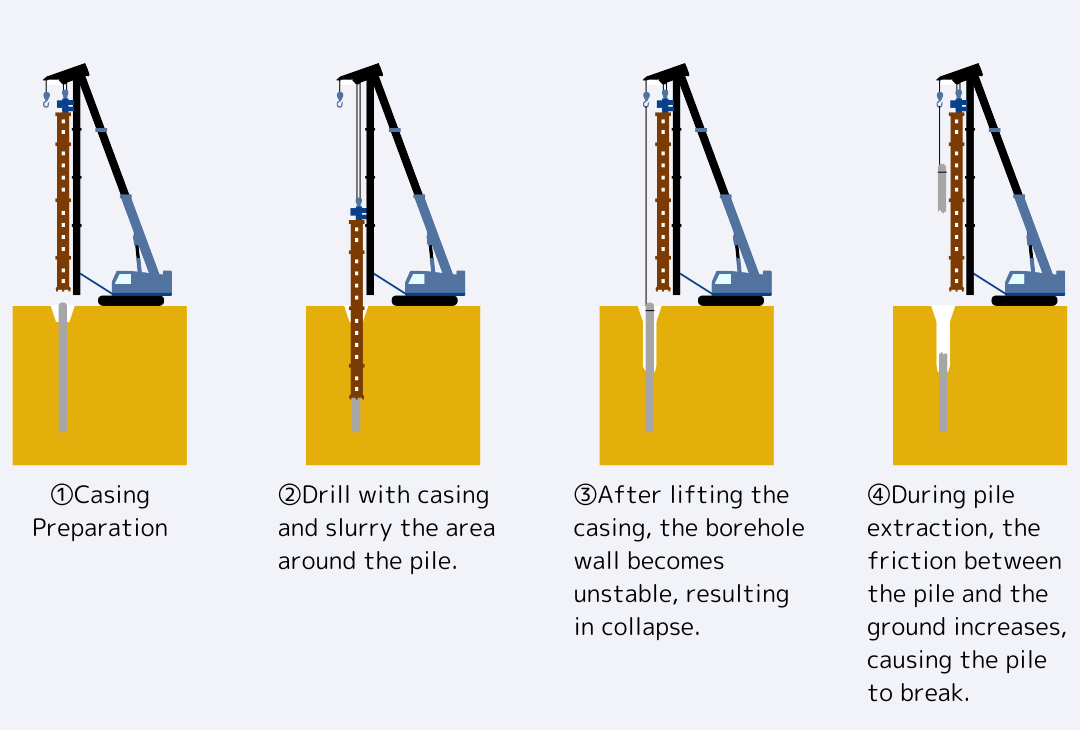

Ⅰ. Causes of Pile Buckling

Drilling is performed using casing, and the area around the pile is turned into sludge. After the casing is lifted, the borehole wall becomes unstable and collapses, increasing the frictional force between the pile and the ground during extraction, leading to pile buckling.

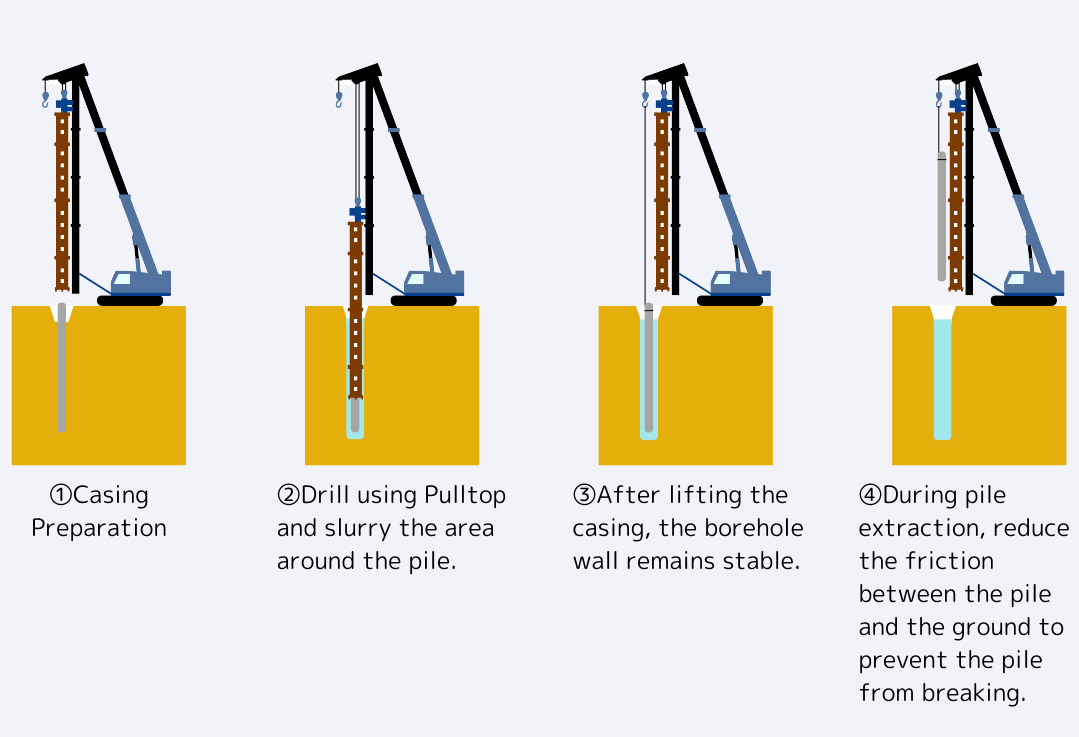

Ⅱ. When Using Pulltop

Drilling is performed using this agent, turning the area around the pile into sludge. After the casing is lifted, the borehole wall remains stable, reducing the frictional force between the pile and the ground during extraction and preventing pile buckling.

Application site

Explanation video

Packaging Type

| Net Weight | 6 kg |

|---|---|

| Package Style | Poly Can |

Formulation example

| Water | Pulltop |

|---|---|

| About 1,000L | 0.5~2 L |

- The above usage amount is only a guideline. Adjust as necessary according to the soil type.

- Add the specified amount of Pulltop to the grout mixer, stir for approximately 2 minutes, and then it is ready for use.

Safety

The 28-day compressive strength of the test specimen, which is a mixture of slurry, soil, and backfill material, is approximately 0.5 N/mm², confirming a strength comparable to that of typical ground.

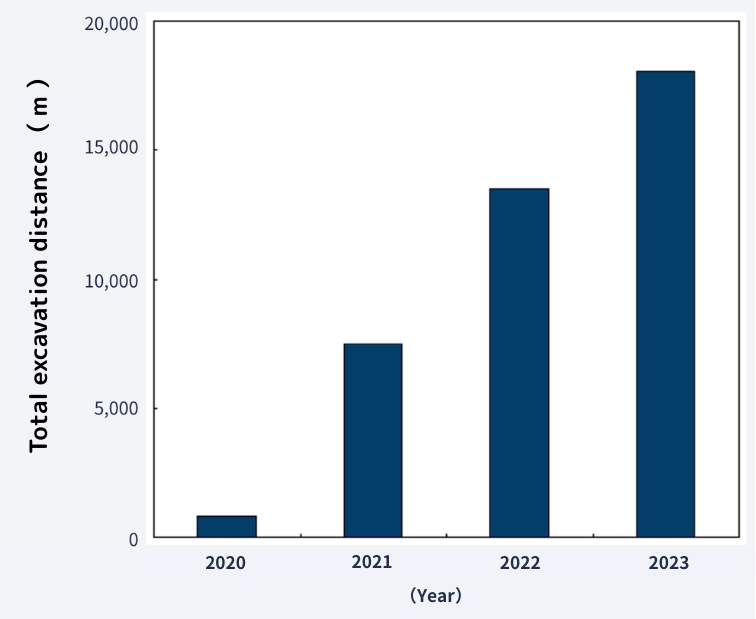

Total excavation distance

※ Excavation distance when the entire shipment of Pulltop is used for Φ500 mm pile removal work.