Distinctive feature

1. Stabilize the borehole wall and prevent piling refusal

In collapsible ground such as gravel layers, the borehole wall is stabilized, allowing piles to be smoothly installed.

2. Easy drilling mud preparation

It is soluble in liquid and can easily create drilling mud in small quantities.

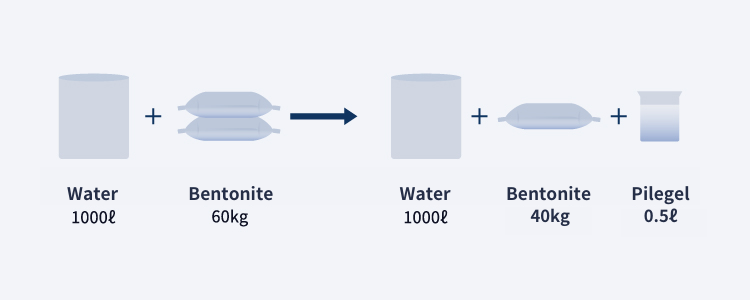

3. Reduce the amount of bentonite by 30%

Example: During drilling of gravel layers (3-5mm)

To prevent the collapse of the borehole wall, 60 kg/m³ of bentonite is typically required. However, by using Pilegel, the amount can be reduced to 40 kg/m³.

※The above usage amount is only a guideline. Please adjust according to the soil type

4. ”Made in Niigata” registered product

Registration number:2021K102

Application site

Explanation video

Packaging Type

| Net Weight | 6 kg |

|---|---|

| Package Style | Poly Can |

Formulation example

| Soil type | Water | Bentonite | Pilegel |

|---|---|---|---|

| Collapsible ground such as gravel layers | About 1,000 L | 20~60 ㎏ | 0.1 L |

- The above usage amount is only a guideline. Please adjust according to the soil conditions.

- Add the prescribed amount of Pilegel to the well-mixed bentonite slurry in a grout mixer, and stir for about 2 minutes before use.

- Avoid stirring for more than 2 minutes.

Safety

The 28-day compressive strength of the specimen mixed with drilling fluid, soil, and pile shaft fixing liquid meets the 0.5 N/mm² requirement according to the standard specifications for public building construction.

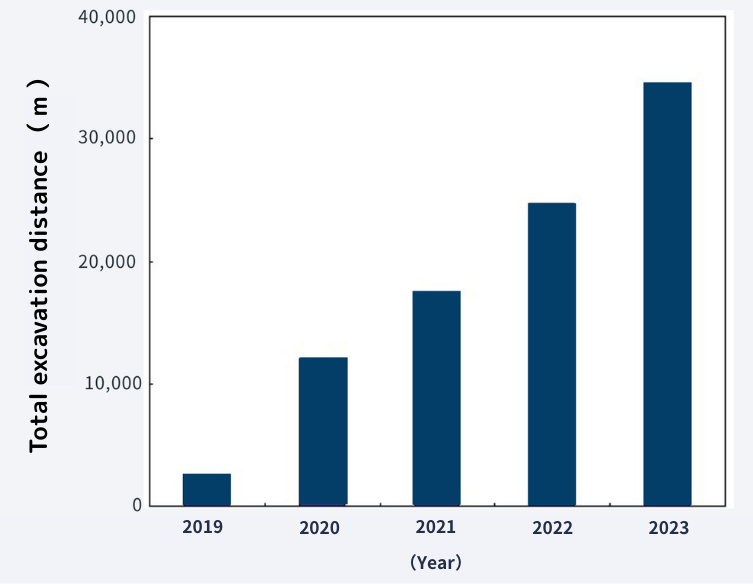

Total excavation distance

※Excavation distance when the total shipment volume of Pilegel is used for pile driving work with a diameter of Φ800 mm.