Distinctive feature

1. Small amount required, easy transportation

Holere requires only about 1/100th of the amount of bentonite to achieve the same viscosity effect. This makes transportation much more convenient. It is especially useful in remote locations, such as mountainous areas where trucks cannot access the site and transportation is difficult.

2.Easy drilling mud preparation

With a small amount of Holere, you can easily create optimal drilling mud for excavation. Compared to conventional bentonite mud, preparing the mud is much easier.

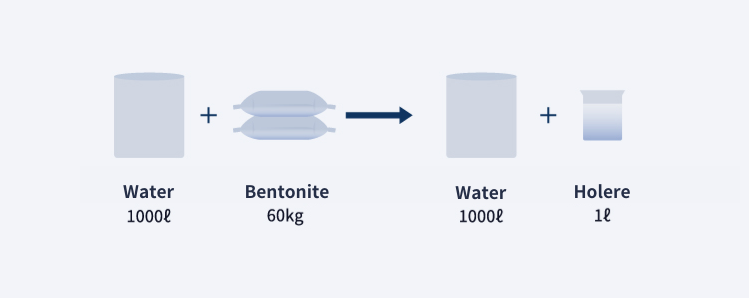

①Clay layer

In stable formations like clay layers, Holere alone shows excellent performance in transporting drill cuttings.

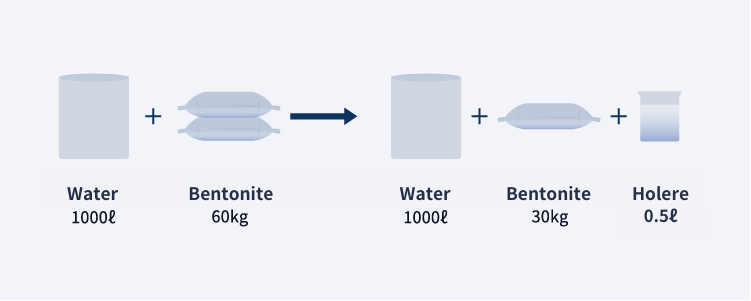

②Sand layer/Gravel layer

In gravel layers, Holere is added to well-mixed bentonite mud. This creates a thin but strong wall, protecting the wellbore and preventing collapse

3. Easy to dissolve and efficient without waste

Holere is a liquid, so it can be used simply by lightly mixing with common tools such as sticks or spatulas.

4. Easily drills

Holere drilling mud has low viscosity and flows smoothly inside the rod with high flow velocity, which reduces the burden on the pump. In contrast, in wells with slower flow velocity, the viscosity increases, making it more effective at carrying drill cuttings, thus improving drilling efficiency.”

Application site

Geotechnical Drilling

Water Well

Ground Improvement

Hot Spring Drilling

Soil Contamination Remediation

Cast-in-place Piling

Anchor Work

Nuclear Plant Grounding Work

Packaging Type

| Net Weight | 6 kg |

|---|---|

| Package Style | Poly Can |

How to use

| Soil type | Water | Bentonite | Holere |

|---|---|---|---|

| Clay layer | 1,000 L | ー | 1 L |

| Sand layer/ Gravel layer | 1,000 L | 30 kg | 0.5 L |

Applicable site

| Product name | Clay layer | Sand layer | Gravel layer |

|---|---|---|---|

| Holere | 〇 | ※ | ※ |

| Holere 2.0 | 〇 | 〇 | ※ |

〇Can be excavated independently. ※Requires combination with bentonite.

Frequently asked questions

- What is the difference between Holere and Holere 2.0?

- Holere can excavate clay layers, while Holere 2.0 can excavate both clay and sand layers.

- When excavating silt and clay layers with Holere drilling mud, the drilling mud may separate into Holere solution and solids. What should be done?

- Adding 'Tasuke' can prevent separation.

- When excavating mudstone, the viscosity of the drilling mud has increased. Is there a good solution?

- Generally, dilution with water is performed, but by using 'Tasuke,' the viscosity can be reduced without increasing the amount of drilling mud.

- What should be done when excavating gravel layers?

- Please add bentonite as needed.

- What is the compatibility with plaster (gypsum) and cement?

- Mixing plaster or cement with Holere drilling mud will impair the mud's functionality. Please do not mix them under any circumstances. If you must use plaster or cement, please contact us.

- Is it possible to perform electrical logging?

- It is possible. Additionally, we have resistivity data and other information available, so please contact us if needed.