Precast Pile Drilling Mud “Pilegel”

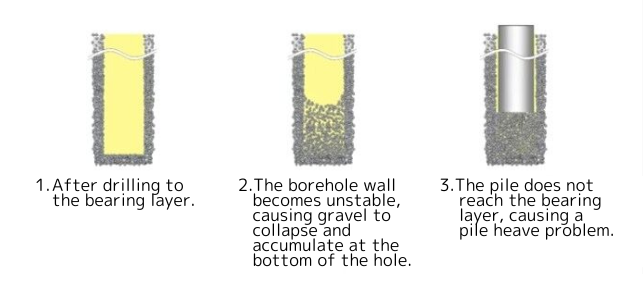

In the past, after drilling, the borehole wall was unstable, causing ground collapse and sediment accumulation at the bottom of the hole, which sometimes led to pile heave.

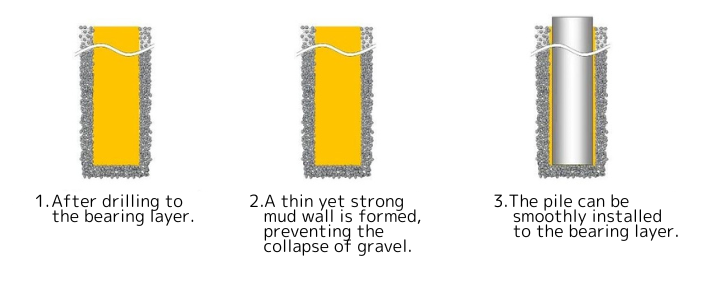

By simply adding a small amount of “Pilegel” to the existing drilling mud, it prevents collapse and helps reduce pile heave!

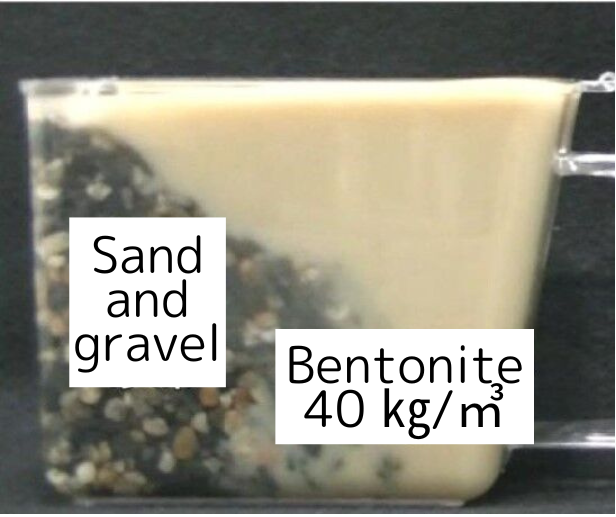

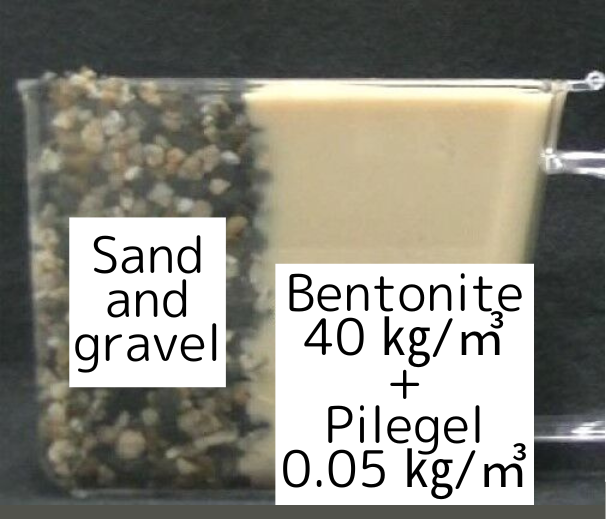

Let’s conduct an experiment to see if Pilegel really makes the ground more resistant to collapse.

By adding just 0.05kg/m³ of Pilegel to 40kg/m³ of bentonite, collapse can be prevented.

By adding Pilegel, the borehole stability improves, allowing ground collapse to be suppressed with less bentonite.

With less bentonite…

Exactly!

As shown in the experiment, in the past, 60kg/m³ of bentonite was required to prevent collapse. However, by using Pilegel, only 40kg/m³ is needed.

This results in a 30% reduction in bentonite usage.

[Image] Actual drilling pit using “Pilegel.”

Pilegel:

・Stabilizes the borehole wall and prevents pile heave.

- ・Reduces bentonite usage by 30%, easing transportation costs, storage space, and the effort required for preparing the drilling mud.

This time, we introduced the precast pile drilling additive “Pilegel.”

We have posted a video on YouTube, so if you’re interested, please feel free to check it out.