目次

Drilled Well Construction

We would like to introduce Holere 2.0, a drilling mud that is highly effective for excavating sandy layers in drilled well construction.

Drilling mud are required to prevent borehole collapse and transport cuttings.

Generally, a clay mineral called bentonite is widely used. However, a large amount is required, necessitating bulk transportation to the site and thorough mixing with a mixer, which presents certain challenges.

Our “Holere 2.0” can solve these challenges!

Feature 1 of Holere 2.0:

Easy drilling mud preparation with less usage, making the work easier!

Holere 2.0 requires only about 1/100th of the amount of bentonite.

As a result, the hassle of transportation is not a concern.

For clay layers and sandy layers

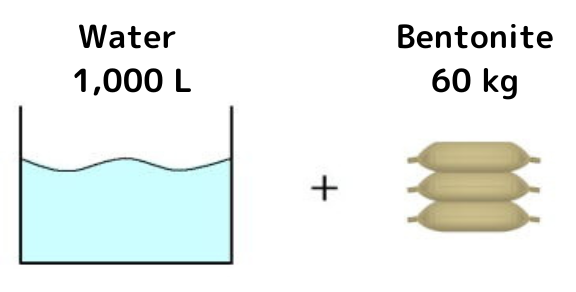

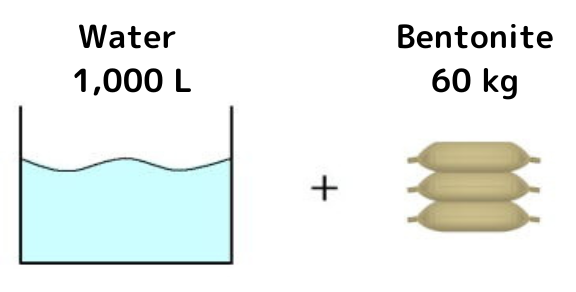

1. Conventional drilling mud

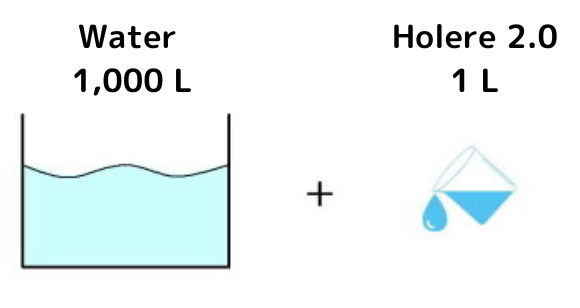

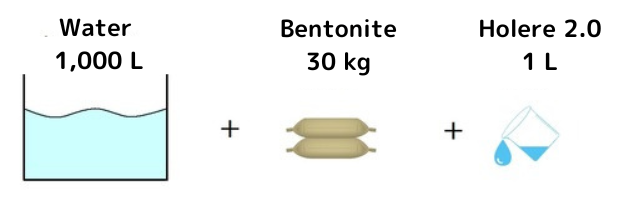

2. New drilling mud , Holere 2.0

For gravel layers

1. Conventional drilling mud

2. New drilling mud , Holere 2.0

Feature 2 of Holere 2.0:

It prevents collapse, making drilling easier.

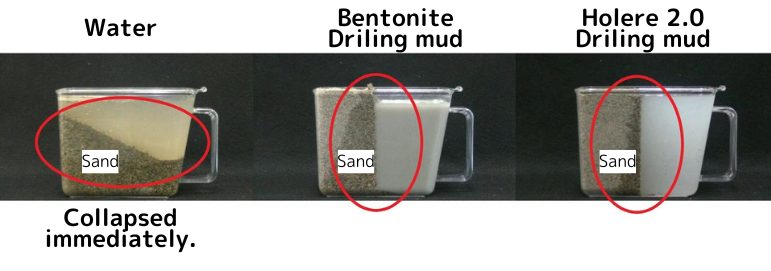

Below is the collapse test setup.

Sand and drilling mud are placed on either side of the partition in the center of the container.

When the partition is removed…↓

The water collapses immediately, but both bentonite and Holere 2.0 were able to prevent the collapse.

From this experiment, it is clear that Holere 2.0 maintains the borehole wall at a level comparable to traditional bentonite.

【Construction examples】

Additionally, we have posted a video on YouTube, so if you’re interested, please feel free to check it out.